English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski

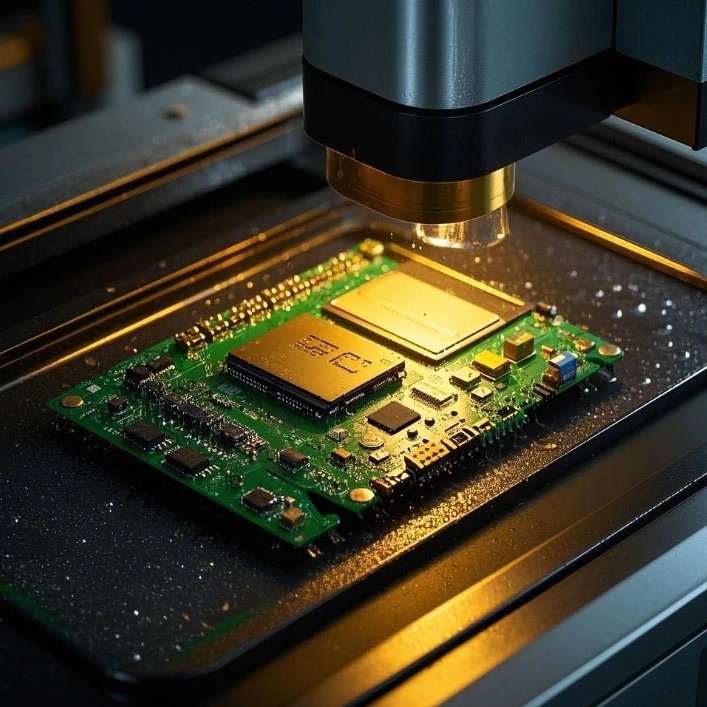

Are You Looking For Industrial PCBA With Advanced Quality Inspection

2025-09-10

When it comes to Industrial Control PCBA, how can you be sure that every component meets the highest standards of reliability and performance? With over two decades of experience in the tech industry, I’ve seen firsthand how advanced inspection methodologies separate exceptional products from the rest. At Greeting, we understand that quality isn’t just a checkbox—it’s the foundation of trust and functionality in industrial applications.

What Defines Advanced Quality Inspection in Industrial PCBA

Not all inspection processes are created equal. In fact, many providers still rely heavily on manual checks, which can lead to inconsistencies, especially in high-volume production. So what should you look for in a modern Industrial Control PCBA quality assurance process?

True advanced inspection integrates automated, data-driven systems at multiple stages. At Greeting, our approach includes:

-

Automated Optical Inspection (AOI): For detecting surface-level defects such as soldering issues, missing components, or misalignments.

-

X-ray Inspection (AXI): Essential for examining hidden connections like BGA (Ball Grid Array) packages and internal layers.

-

In-Circuit Testing (ICT): Verifies electrical performance and ensures all components meet specified values.

-

Functional Circuit Testing: Validates that the assembled board operates according to design specifications under real-world conditions.

These aren’t just steps in a process—they are part of a philosophy that prioritizes prevention over correction. For us, it’s personal: we’ve seen how a single fault can lead to system failures, costly recalls, or even safety hazards. That’s why we’ve built our entire Industrial Control PCBA manufacturing workflow around inspection technologies that catch errors before they become problems.

How Do Our Technical Specifications Meet Your Industrial Needs

When you’re sourcing Industrial Control PCBA, you need more than just a list of features—you need guarantees. Here’s how Greeting ensures every board we produce is built for durability, precision, and long-term performance.

Our technical capabilities include:

| Feature | Specification |

|---|---|

| Board Layers | Up to 22 layers |

| Minimum Trace Width | 3 mil |

| Material Options | FR-4, High-Tg FR-4, Metal Core, Polyimide, Rogers |

| Soldering Technology | Lead-free (ROHS compliant), selective soldering |

| Thermal Management | Integrated heat sinks, thermal vias, and advanced cooling simulations |

| Coating & Protection | Conformal coating (acrylic, silicone, urethane), IP67 sealing options |

| Testing Coverage | 100% electrical testing, AOI and AXI applied to all boards |

But numbers only tell part of the story. What truly sets Greeting apart is how we tailor these parameters to your environment. Whether you’re operating in extreme temperatures, dealing with high vibration, or require compliance with specific industry standards, we design each Industrial Control PCBA to not only meet but exceed those demands.

Why Should You Care About Supply Chain Transparency

Have you ever wondered where your components come from? In today’s global landscape, transparency isn’t optional—it’s critical. We partner with certified suppliers and provide full traceability for every part used in your Industrial Control PCBA. This means you’ll always know the origin of your components, their lifecycle, and their compliance status.

Can Your PCBA Provider Keep Up With Innovation

Technology evolves rapidly. What was cutting-edge five years ago might be obsolete today. At Greeting, we continuously invest in the latest inspection technologies and training programs for our team. This commitment ensures that every Industrial Control PCBA we deliver leverages the most advanced methods available, giving you a competitive edge and peace of mind.

Ready to Experience the Difference

If you’re looking for a partner who treats your success as their own, look no further. Greeting is dedicated to delivering industrial-grade PCBA solutions that stand up to the toughest conditions. Let us show you how our advanced quality inspection process can enhance your product’s reliability and performance.

Contact us today to discuss your project needs or request a personalized quote.