Article Summary: Magnetic beads are tiny yet powerful components widely used in modern electronics. In this article, we explore their functions, types, applications, and benefits. You’ll also discover how Greeting Electronics ensures high-quality magnetic beads for various industries.

Table of Contents

- Introduction to Magnetic Beads

- Types of Magnetic Beads

- How Magnetic Beads Work

- Applications in Modern Electronics

- Benefits of Using Magnetic Beads

- How to Choose the Right Magnetic Beads

- FAQ

- Conclusion & Contact

Introduction to Magnetic Beads

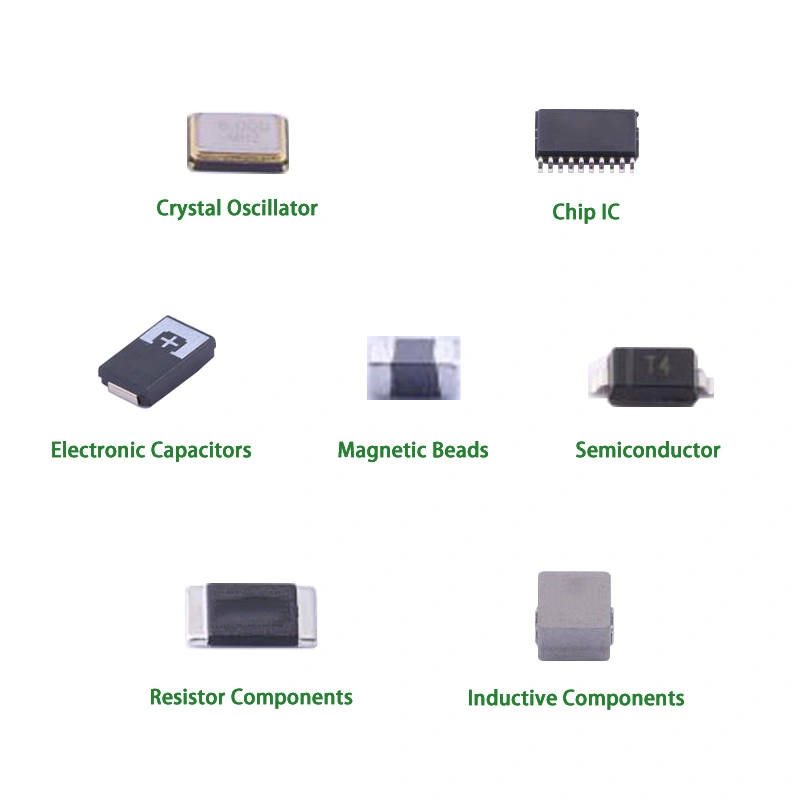

Magnetic beads are small inductive components widely used in electronic circuits to suppress electromagnetic interference (EMI), stabilize signals, and enhance device performance. They are crafted from ferrite or metal alloys that exhibit strong magnetic properties. Shenzhen Greeting Electronics specializes in manufacturing high-quality magnetic beads that meet rigorous industry standards.

Types of Magnetic Beads

Understanding the different types of magnetic beads is crucial for selecting the right component for your application.

| Type | Material | Frequency Range | Application |

|---|---|---|---|

| Chip Magnetic Beads | Ferrite | 10kHz - 100MHz | Signal filtering in PCB assemblies |

| Through-Hole Magnetic Beads | Ferrite / Alloy | 50kHz - 500MHz | Power line EMI suppression |

| Surface-Mount Magnetic Beads | Ferrite | 10kHz - 200MHz | Consumer electronics and mobile devices |

- Chip Magnetic Beads: Ideal for compact circuit boards.

- Through-Hole Magnetic Beads: Provide high current handling.

- Surface-Mount Magnetic Beads: Popular for automated PCB assembly.

How Magnetic Beads Work

Magnetic beads function as passive components that store and release magnetic energy. Their primary role is to filter high-frequency noise and stabilize current flow in sensitive circuits. The working principle involves:

- EMI absorption: Magnetic beads dissipate unwanted high-frequency signals as heat.

- Inductive reactance: They resist sudden changes in current, protecting sensitive components.

- Signal integrity enhancement: By filtering noise, they maintain signal clarity in high-speed electronics.

Greeting Electronics ensures precise manufacturing of magnetic beads to guarantee consistent inductance and minimal signal distortion.

Applications in Modern Electronics

Magnetic beads are used across diverse industries, including:

- PCB Assemblies

- Mobile Phones and Tablets

- Medical Equipment

- Automotive Electronics

- LED Lighting Systems

Example: In smartphone PCBs, surface-mount magnetic beads filter EMI from power lines, ensuring stable operation and reduced noise.

Benefits of Using Magnetic Beads

Magnetic beads provide multiple advantages:

- High-Frequency Noise Suppression: Prevents interference with sensitive electronics.

- Compact Design: Small size fits modern miniaturized PCBs.

- Cost-Effective: Provides EMI suppression without expensive shielding solutions.

- Enhanced Device Reliability: Protects components from current spikes.

How to Choose the Right Magnetic Beads

Selecting the right magnetic beads requires consideration of several factors:

| Factor | Recommendation | Impact |

|---|---|---|

| Frequency Range | Match bead specification to circuit frequency | Optimal EMI suppression |

| Current Handling | Choose beads rated for expected current | Prevents saturation and overheating |

| Size & Form Factor | Chip or surface-mount for compact designs | Easy PCB integration |

| Material | Ferrite or alloy based on performance needs | Stable inductance and durability |

Greeting Electronics offers a wide range of magnetic beads with detailed specifications, making component selection simple for engineers and designers.

FAQ

Q1: What are magnetic beads made of?

Magnetic beads are typically made from ferrite or metal alloys that exhibit strong magnetic properties suitable for EMI suppression.

Q2: Can magnetic beads handle high currents?

Yes, through-hole magnetic beads are designed for higher current handling compared to surface-mount types.

Q3: Where are magnetic beads commonly used?

They are commonly used in mobile devices, automotive electronics, LED lighting, and PCB assemblies to filter noise and stabilize circuits.

Q4: How do I choose the right magnetic bead for my project?

Consider frequency range, current rating, size, and material. Greeting Electronics provides detailed product specifications to guide your selection.

Q5: Why choose Greeting Electronics for magnetic beads?

Greeting Electronics guarantees high-quality magnetic beads with fast delivery and excellent customer support, ensuring reliability in your projects.

Conclusion & Contact

Magnetic beads are indispensable in modern electronics for noise suppression and signal integrity. Choosing high-quality components from a trusted manufacturer like Greeting Electronics ensures optimal performance and device reliability.

For customized solutions or bulk orders, contact us today to discuss your requirements with our experts.