English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski

How Can PCB Clone Help You Rescue a Board With Missing Design Files?

Abstract

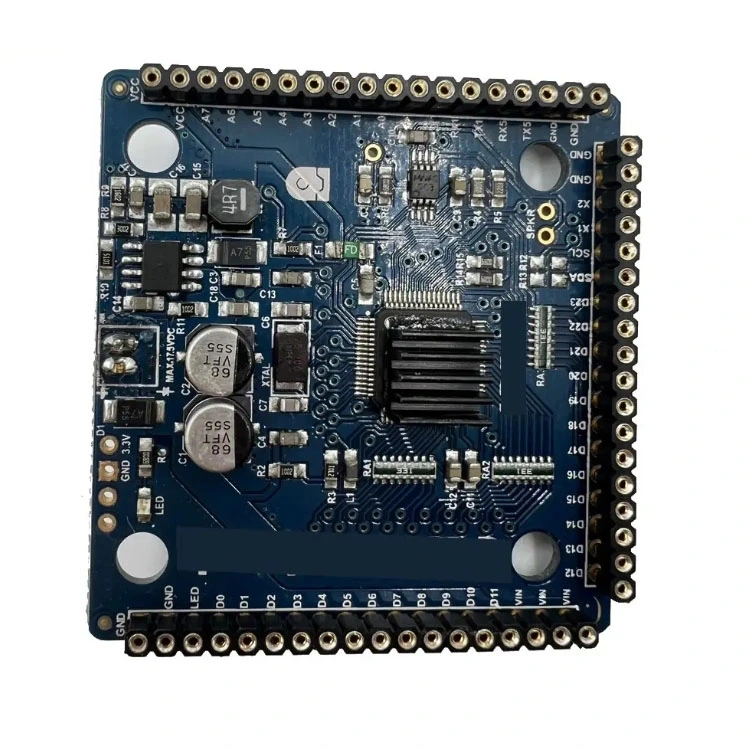

When a critical electronic product is still in service but the original CAD data is gone, a single failed board can turn into weeks of downtime, expensive redesign cycles, or a scramble for unreliable substitutes. PCB Clone is a structured reverse-engineering approach that recreates the manufacturing-ready data of an existing circuit board so you can reproduce it, repair it at scale, or keep an older product line alive while you plan a long-term upgrade. This article explains when cloning makes sense, what information you can realistically recover, how to minimize risk, and what a responsible cloning workflow looks like from the first inspection to final validation.

- Best fit when you legally own the board design or have permission to reproduce it.

- Not magic if the board is heavily damaged, potted, or uses custom silicon and encrypted firmware.

- Highest value when uptime matters and replacements are unavailable or inconsistent.

Table of Contents

- Outline at a Glance

- What Pain Points Does PCB Cloning Solve

- What PCB Clone Really Means in Practice

- When Cloning Is the Smartest Option and When It Is Not

- A Practical PCB Clone Workflow From Start to Finish

- How to Protect Quality and Reliability

- What Drives Cost and Lead Time

- What You Should Prepare Before Requesting a Quote

- How to Choose a Responsible Cloning Partner

- FAQ

- Next Step

Outline at a Glance

- Clarify your goal: replacement, repair stock, lifecycle extension, or redesign bridge.

- Confirm ownership and permissions.

- Capture board data: dimensions, layers, stack-up hints, and component mapping.

- Recreate manufacturing files and electrical intent: Gerber, drill, netlist, BOM.

- Prototype, validate, and lock a controlled revision.

- Establish ongoing controls: incoming inspection, functional testing, and traceability.

What Pain Points Does PCB Cloning Solve

Most teams do not decide to clone a board because it sounds fun. They do it because the alternative is worse. Here are the most common situations where PCB Clone removes real operational pain:

- No source files because the original designer left, data was lost, or the product was acquired years later.

- End-of-life components force you to either redesign urgently or source risky gray-market stock.

- Field repairs need stable replacement boards, not random “compatible” alternatives with unknown stack-up or copper weights.

- Compliance pressure requires consistent manufacturing and documentation to pass audits or internal quality gates.

- Time-to-recover matters more than “perfect modern design,” especially for industrial controls and legacy instrumentation.

A factory line stops because a controller board fails. The OEM has stopped supplying spares. Rebuilding the entire control system is a big project, but management needs a solution in weeks, not quarters. Cloning the board can keep production running while you plan the long-term modernization.

What PCB Clone Really Means in Practice

People use “cloning” casually, but in engineering terms it usually includes three layers of work:

- Physical replication recreating the board outline, mounting holes, connectors, layer count, and stack-up behavior as closely as possible.

- Electrical reconstruction capturing copper connectivity so the reproduced board matches the original netlist intent.

- Component recovery identifying parts, footprints, values, alternates, and assembly notes so the board can be built consistently.

The deliverables often include manufacturing-ready outputs such as Gerber or ODB++ data, drill files, pick-and-place data when feasible, a bill of materials, and a verified netlist. If your goal is long-term maintainability, many teams also ask for a reconstructed schematic so future troubleshooting does not rely on guesswork.

When Cloning Is the Smartest Option and When It Is Not

Cloning is a tool, not a default. Use it when it matches your risk profile and timeline.

| Scenario | Why PCB Clone Helps | Potential Limits |

|---|---|---|

| Spare boards needed for legacy equipment | Fastest route to stable replacements without full redesign | May still need part alternates if components are discontinued |

| Board data lost but product still sells | Recreates production files so manufacturing becomes predictable again | Custom firmware or programmed ICs may require separate handling |

| Urgent downtime and no reliable supplier | Enables controlled, repeatable builds with testing | Severely damaged boards reduce data recovery accuracy |

| Major functionality changes planned | Cloned board can act as a bridge while redesign is in progress | If you will redesign anyway, avoid over-investing in perfect reconstruction |

- If you do not own the design rights or do not have permission to reproduce the board.

- If the PCB is only one part of the problem and the real issue is firmware, calibration, or system-level safety certification.

- If you need major performance changes that require a new layout, not a replica.

A Practical PCB Clone Workflow From Start to Finish

A reliable clone is the result of disciplined steps, not a single scan. Below is a workflow that engineering teams commonly use to reduce surprises.

-

Step 1: Intake and goal definition

- Confirm what “success” means: exact replacement, form-fit-function, or functional-equivalent with alternates.

- Gather context: operating environment, failure mode, expected volume, and timeline.

-

Step 2: Non-destructive inspection

- Measure outline, hole locations, connector keying, and mechanical constraints.

- Identify layer indicators and manufacturing features such as impedance traces, via types, and copper pours.

-

Step 3: Data capture for copper and layers

- High-resolution imaging for top and bottom layers to map traces and reference designators.

- Controlled layer reveal when necessary for multilayer boards, performed carefully to preserve fidelity.

-

Step 4: Component identification and BOM reconstruction

- Cross-check markings, packages, and values; confirm polarities and pin-1 orientation.

- Define approved alternates to prevent future shortages.

-

Step 5: Recreate manufacturing outputs

- Generate layout files and manufacturing data, including drill and solder mask definitions.

- Extract connectivity and run netlist consistency checks against the recovered copper.

-

Step 6: Prototype build and validation

- Build prototypes under controlled process parameters.

- Perform electrical tests such as continuity, impedance checks when relevant, and functional verification in the real system.

-

Step 7: Revision lock and documentation

- Freeze an auditable revision with change logs and test records.

- Create service-friendly outputs if you plan to maintain the product for years.

How to Protect Quality and Reliability

The biggest fear customers have is simple: “Will the cloned board behave exactly like the original, and will it keep behaving that way after deployment?” You can reduce that risk by treating cloning like a controlled engineering project.

- Stack-up discipline replicate layer count, copper thickness, dielectric behavior, and controlled-impedance structures when present.

- Connector accuracy mechanical mismatch is a fast way to fail, even if the circuit is correct.

- Component authenticity establish traceable sourcing and avoid unknown supply channels for critical ICs.

- Test strategy define a test plan beyond “it powers on,” including load conditions, thermal behavior, and edge cases.

- Process control specify soldering profiles, inspection standards, and acceptance criteria from the beginning.

If your board includes high-speed interfaces, RF paths, or tight power integrity requirements, treat the prototype stage as mandatory. Even small differences in solder mask, dielectric properties, or via style can change performance.

What Drives Cost and Lead Time

Pricing varies because complexity varies. Instead of guessing, focus on the levers that matter:

- Layer count and density more layers and fine pitch components increase reconstruction effort.

- Board condition burnt, corroded, or physically modified boards reduce recoverable detail.

- Availability of parts discontinued or hard-to-identify components add sourcing and validation time.

- Documentation level requested a full schematic reconstruction takes longer than a form-fit-function clone.

- Validation expectations functional testing in your real system is the difference between “looks similar” and “works reliably.”

What You Should Prepare Before Requesting a Quote

You will get a faster, more accurate plan if you prepare a small package of information. Use this checklist.

- At least 2 working samples when possible, plus 1 failed sample if you want failure analysis.

- Photos of the board installed in the product to confirm mechanical constraints and connector orientation.

- Your target quantity and whether you need ongoing supply or a one-time batch.

- Any known operating conditions: temperature range, vibration, humidity, duty cycle, load profiles.

- Any clues you still have: partial Gerbers, PDFs, old BOM exports, silkscreen notes, or test procedures.

- Clarification on firmware and programmed parts: do you have the binaries, keys, or programming method?

If you can label what the board does inside the system and share a basic block diagram, engineers can validate behavior faster during functional tests.

How to Choose a Responsible Cloning Partner

You are not only buying a board. You are buying confidence that the reproduction is controlled, documented, and repeatable. Here is what to look for in a supplier relationship:

- Clear boundaries on legality and permissions a serious provider will ask about ownership and authorized use.

- Engineering communication you should be able to discuss stack-up, alternates, and test methods in plain language.

- Verification mindset look for netlist checks, prototype validation, and traceable procurement.

- Revision control the cloned design should have a defined version so future batches stay consistent.

At Shenzhen Greeting Electronics Co., Ltd., teams typically approach cloning as an engineering continuity project: clarify targets, recover critical manufacturing data, validate prototypes in real conditions, then lock a stable revision for repeat production. If you need a bridge solution while planning a redesign, a controlled clone can buy you time without sacrificing reliability.

FAQ

Can a PCB clone be identical to the original board

It can be form-fit-function equivalent and often extremely close, but “identical” depends on what you mean. Mechanical dimensions and connectivity can typically be matched very well. Exact material behavior, proprietary components, and firmware details may require additional work or may be impossible to recreate without the original data.

Do I need multiple samples

Multiple samples reduce risk because engineers can compare markings, confirm ambiguous traces, and avoid copying a board that was already modified or repaired. If you only have one sample, expect more validation steps and a more conservative timeline.

What if some components are no longer available

A practical clone plan often includes component alternates. The key is to validate that alternates match the electrical requirements and fit the footprint, then confirm behavior through testing under your real load and environment.

Will cloning solve firmware and programming

Cloning the PCB does not automatically recreate locked firmware. If the board contains programmed microcontrollers, secure elements, or encrypted memory, you may need the original binaries, a legal programming method, or an authorized replacement part strategy.

How do I reduce the chance of field failures

Ask for a validation plan and treat prototypes as mandatory for mission-critical systems. Define acceptance criteria, include functional tests that mimic real operating conditions, and lock a revision with traceable procurement and inspection standards.

Next Step

If you are dealing with missing files, end-of-life sourcing, or urgent downtime, a well-managed PCB Clone project can give you a stable, test-verified path back to production. Share your board photos, target quantity, and system context, and request a practical recovery plan that includes validation and revision control.

Ready to bring your legacy board back to life without the guesswork? contact us to discuss your samples and goals, and we will help you map out a safe, test-driven cloning plan that fits your timeline.