English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski

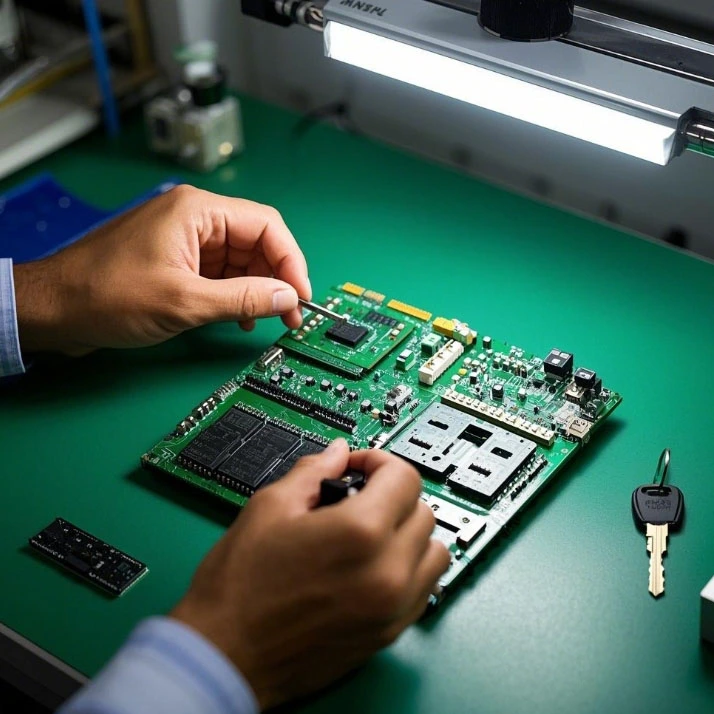

What Is the Best Turnkey PCB Assembly Solution for Your Project

How many hours have you spent this month just managing your PCB supply chain? Coordinating with a fabricator here, a component supplier there, and a separate assembly house can feel like a full-time job. I have seen countless projects get delayed not by design flaws, but by logistical nightmares. That is why the question is not just about assembly; it is about finding a true partner who can shoulder the entire burden. So, let us break down what truly makes for the best turnkey PCB assembly service.

What Exactly Does a Turnkey PCB Assembly Service Handle For You

Think of us as your single point of contact. From the moment you send us your design files, we take complete ownership. A true turnkey process means we manage every single step under one roof. This includes:

-

Procurement: We source all components, leveraging our long-standing relationships with distributors to get the best prices and avoid counterfeit parts.

-

PCB Fabrication: We manufacture the bare boards ourselves to ensure perfect quality and fit for assembly.

-

Assembly: Our state-of-the-art SMT and thru-hole lines populate your boards with precision.

-

Testing: We do not just build; we verify with rigorous in-circuit (ICT) and functional testing (FCT).

-

Box Build: We can often handle the final product integration as well.

The value of a seamless PCB Assembly Service is the gift of time. It allows you to focus on your core competency—innovation and design.

Which Technical Specifications Truly Matter in a PCB Partner

This is where the rubber meets the road. A great partner must have the capabilities to match your project's demands, from a simple prototype to complex, high-volume production. Do not just take their word for it; ask for their specs. Here is what we offer at Greeting:

Our Key Capabilities at a Glance

| Feature Category | Our Specification | Why This Matters to Your Project |

|---|---|---|

| Layer Support | Up to 22 layers | Handles incredibly complex and dense designs. |

| Minimum Trace/Space | 3/3 mil | Supports advanced, miniaturized components and HDI designs. |

| Board Thickness | 0.4mm - 4.0mm | Flexibility for rigid, flexible, and rigid-flex applications. |

| SMT Placement Speed | 0.035 seconds/chip | High-speed accuracy for volume production without sacrificing quality. |

| Placement Accuracy | ±25μm @ 3σ | Ensures even the smallest BGA and micro-BGA components are placed perfectly. |

| Smallest Component | 0201 (metric 0603), 0.4mm BGA | Capability to work with the latest, most compact parts. |

A list of our core testing services is non-negotiable for a reliable PCB Assembly Service:

-

Automated Optical Inspection (AOI)

-

X-Ray Inspection for BGA and hidden joints

-

In-Circuit Test (ICT)

-

Functional Test (FCT)

-

Burn-in Testing

How Can the Right Partner Solve Common PCB Assembly Pain Points

I have listened to engineers and project managers for two decades, and the frustrations are always the same. Let us address them head-on.

“I am constantly facing delays.” This is why we provide real-time tracking portals. You see the status of your order, from component procurement to final shipping, eliminating anxious emails and phone calls.

“My last vendor had terrible quality control.” Our investment in the AOI and X-ray equipment listed above is our commitment to zero-defect builds. We catch problems before they become your problems.

“I got killed by hidden costs.” Our turnkey PCB assembly service model provides a single, upfront quote. You know the cost for boards, parts, assembly, and testing from day one. No surprises.

This proactive approach to communication and quality control is what defines a modern PCB Assembly Service. It is about building trust, not just boards.

Are You Ready to Streamline Your Production Process

Choosing a partner is more than just comparing charts. It is about finding a team that listens, understands your goals, and has the technical prowess to execute. Your project deserves a PCB Assembly Service that acts as an extension of your own engineering team, dedicated to making your vision a manufacturable reality.

We invite you to experience the difference that true ownership and expertise can make. Contact us today for a no-obligation consultation and quote. Let us discuss your specific project needs and show you how our PCB Assembly Service can become your most valuable advantage.